You might have never noticed, but release paper (also known as silicone oil paper) has already penetrated every corner of life—from the diaphragm of mobile phone batteries to food packaging labels, from medical tape to the precise assembly of electronic components. Its "non-stick" characteristic allows numerous products to operate efficiently. Today, we will unveil its mystery and explore the core differences and application scenarios of various types such as silicone release paper and adhesive release paper.

The Basic Functions of Release Paper: Release Force and Precision Control

The core performance of release paper lies in the release force—the force needed to separate the coating from the adhesive. This force cannot be too strong (otherwise it will be difficult to peel off), nor too weak (otherwise the adhesive layer cannot be fixed). For example:

Label Industry: The release force needs to be controlled between 20-50g/25mm to ensure that labels can be easily peeled off without spilling adhesive.

Electronic Tape: The release force can be as low as 5g/25mm to avoid damaging the surface of precision components.

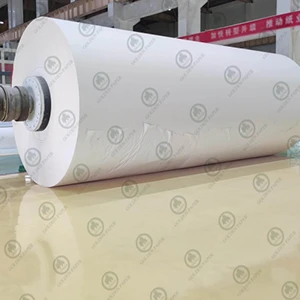

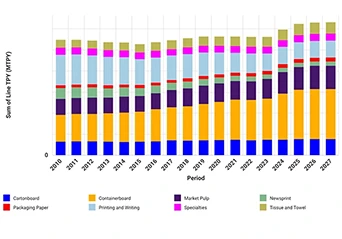

Behind this precise control is the sophisticated coordination of silicone oil coating technology, substrate selection (such as glassine paper and CCK paper), and the thickness of the coating. Take the Asian market as an example: In 2015, 47% of silicone oil paper was used for self-adhesive labels, while heat-resistant polyolefin-coated paper, which adapts to humid and hot climates, accounted for 29% of the market share (data source: AWA report).

Silicone Release Paper: Guardian of High-Temperature and High-Stickiness Scenarios

Features

Silicone Coating: Provides excellent non-stick properties and high-temperature resistance (up to more than 200°C).

Substrate Selection: Glassine paper (smooth surface) and CCK paper (strong moisture resistance) are mainstream choices.

Application Scenarios

Food Baking: Silicone paper is used as a baking pan liner, oil-resistant and high-temperature resistant to prevent food from sticking.

Electronic Manufacturing: Used for flexible circuit board (FPC) lamination to ensure no residue after high-temperature compression.

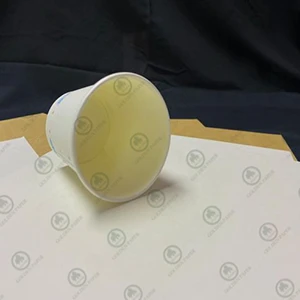

Medical Dressings: Silicone release film protects the adhesive layer, making it painless and non-damaging to the skin when peeled off.

Industry Trends: The annual growth rate of the Asian silicone paper market is 7.6%, with significant contributions from the pharmaceutical and tape sectors (AWA data).

Adhesive Release Paper: The Best Partner for Tape and Labels

Core Functions

Protect the adhesive layer from contamination while ensuring smooth peeling during use.

Categories and Advantages

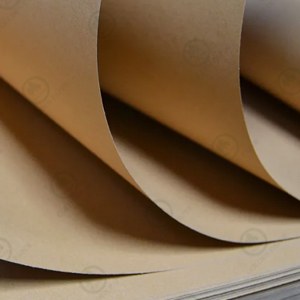

Single-Sided Release Paper: Commonly used in double-sided tapes, the substrate is often high-density kraft paper, tear-resistant.

Double-Sided Release Paper: Used for high-precision labels, such as electronic component packaging, requiring strict control over coating uniformity.

Industry Pain Points Breakthrough

Traditional release paper is easily affected by humidity, causing curling, while glass fiber release paper enhances the substrate's moisture resistance, becoming the preferred choice for self-adhesive labels and medical films. For example, Zhejiang Xili Release Paper Company offers products with a basis weight range of 40-300g/m² and customizable silicone content to meet the diverse needs from industrial tapes to food packaging.

Cross-Border Innovation of Release Paper: From Artificial Leather to Microelectronics

The application of release paper has long surpassed traditional fields:

Artificial Leather Manufacturing: As a carrier of PVC/PU leather, the texture of the release paper determines the surface texture of the leather (domestic annual demand exceeds 60,000 tons).

Microelectronic Carrier Tape: Jin Chang Paper Industry has developed anti-static release paper, breaking foreign monopolies, used for chip transportation, with both flexibility and impact resistance.

Green Packaging: Degradable silicone oil paper (such as PLA coating) is replacing plastic, becoming the new favorite for food packaging.

How to Choose Suitable Release Paper?

Three steps based on needs:

Clarify the Purpose: Choose silicone release paper for high-temperature environments, and glass fiber substrates for precision labels.

Test Performance: Release force, temperature resistance, and moisture resistance need to be verified in actual scenarios.

Evaluate Suppliers: Focus on technical customization capabilities (such as Golden Paper Group providing a full range of products from 40g to 300g) and environmental certifications (such as FSC, ISO 14001).

From silicone release to adhesive protection, the "invisible value" of release paper is driving the dual upgrade of industrial efficiency and environmental protection. If you need high-precision, customized release paper solutions, Golden Paper Group, with 20 years of industry experience and a service system covering 100 countries, can provide you with comprehensive support from food-grade silicone paper to electronics-specific release films—after all, a breakthrough in a single sheet of paper could be the starting point for your product innovation.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id